The surface quality before chroming guarantees the quality of chromed bars. That’s the reason why at Uranie International, the operations to prepare the polished and ground bars before

plating are meticulesly performed.

100% reliable raw materials

Peeling

Purchased with a stock allowance hot rolled bars are peeled to remove surface steel defects, improve the geometry and calibrate to requested size.

Straightening

Straightening is performed twice, before and after the peeling to guarantee perfect straightness.

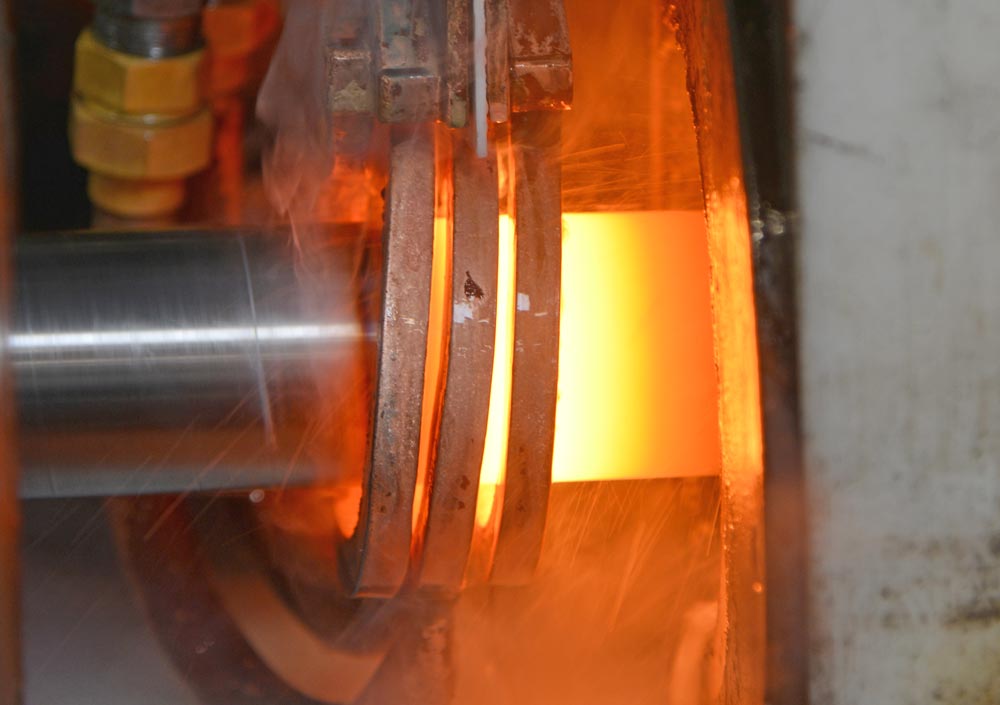

Heat treatment induction hardening (optional)

The surface hardness is improved with an excellent control of the hardness depth and of the hardness

grade, thanks to a fully automatic heat treatment machine, taking into account the different parameters like the steel grade, the diameter and the customer’s technical specifications.

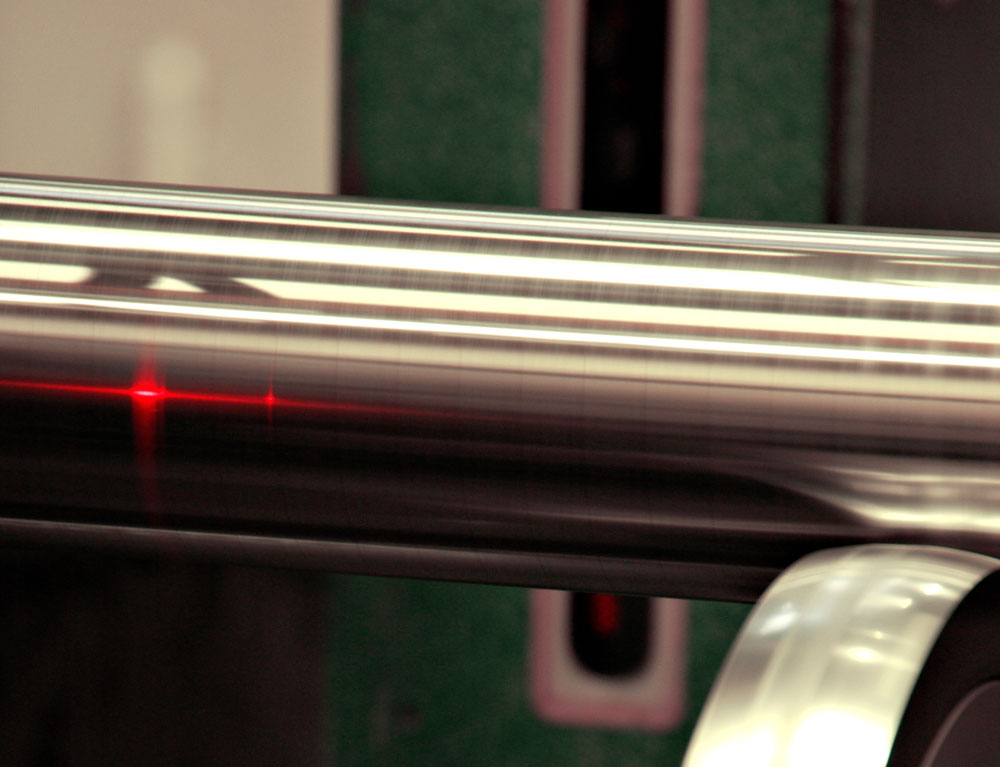

Grinding and polishing

These operations performed in-line on centerless grinding machines allow to reach the perfect dimensional precision and surface finish.

Share